History of Dartboards

Dartboards, wood, clay and sisal

![]()

The history of darts as a modern game has its origins in France. The game made its way to the shores of the UK via the funfair where for a small wager the public could bet on their ability to throw a set of darts accurately at a wooden target. Usefully the target would have been a segmented circular board. Each segment would have had a number and the basic objective would have been to score under or over a given number. Missing the board or a bounce out would mean either a score of zero or a points value added to your score depending on the game rules.

The earliest dartboards that were made consisted of a small 7-9” diameter wooden board that consisted of several concentric coloured circle bands and a centre bullseye. The centre would have had the highest scoring value as it would have been the hardest to hit. The circle bands then decreased in value from the centre out. Darts would have also been made from wood with a metal point and turkey or other feathered flights. However, in the UK the boards that we have generally used seemed to have been an extension from the fairground attraction.

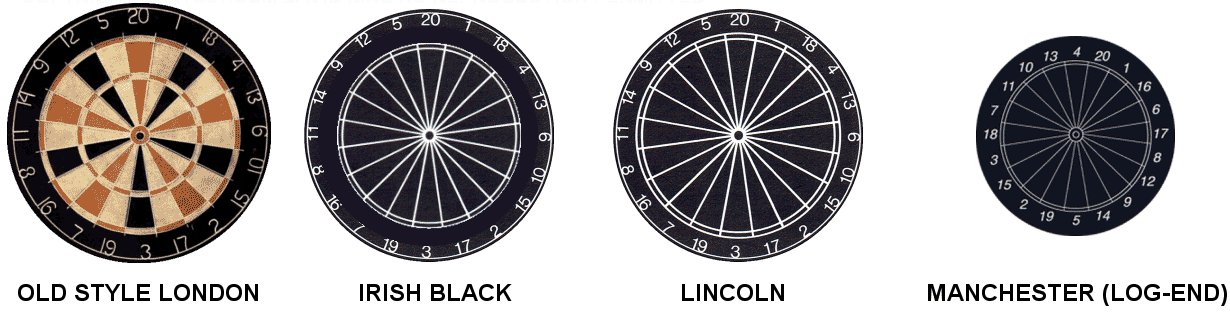

UK / England Regional Dartboard

Most regions of the UK at one time or another adopted their own style dartboard. Leagues would have been confined to neighbouring pubs or not at all. The variation of the regional dartboards has been extensive; however, few survive and are played on today.

In the late 1880’s up until 1920’s most dartboards were constructed using elm or other softwoods. Poplar was one other wood used. Although a soft wood it is considered to be a hardwood.

A dartboard would be constructed using a soaked log-end and thin metal strip would be hammered directly into the wood for form the segmented areas and the numbers or wires were nailed to the board to create the segments. It seems the construction varied depending on the board and the craftsman.

Once the board was complete it would be dyed black. Black offset the silver wire well and allowed both a scorer and player to see where a dart landed.

Boards made this way were the original Yorkshire dartboard, the Kent (Doubles), the Irish Black, the Lincoln, the Grimsby and one that has really stood the test of time the Manchester log-end dartboard.

The dartboards would have to be kept wet to avoid the boards drying out and splitting. After each use, the dartboard would have been removed and submerged under water and only removed an hour or so before the board would be used again. The soaking not only helped the board to stay on one piece but it also helped the hole punctures made by the darts close up.

An alternative to wood was soought. Soaking the dartboard for some was not kept up leading to board failure and unhealable cracking.

Clay and Sisal Dartboards

In 1919 Edward (Ted) Leggat and industrial chemist went into business selling a new modelling clay he had invented. At the time the clay was unlike any other on the market because it had no odour, a selling point Ted would use in the name of the product ‘Nodor’. The modelling clay was like a more common plasticine many will be familiar with today.

In the early 1920s, Ted thought his new ‘Nodor’ clay could be a good material for making dartboards. The dart would embed into a clay slab quite easily and the holes it made could easily be rolled out and repaired. In 1923, Nodor marketed their first clay dartboard. However, it wasn’t a great success that Ted hoped it would be. Ted later added elm dartboards and brass darts to the range.

In 1931 a landlord Frank Dabbs, a Kent publican, approached Ted with an idea that would revolutionise the dartboard we play on today. Frank suggested a dartboard made from short pieces of rope which would be bound tightly to form the dartboard playing surface. Ted refined Frank's idea and patented a new dartboard along with Frank. The new rope or sisal dartboard was launched and was known as the Nodor Original Bristle dartboard.

The fibre used to make the board was sisal which comes from the sisal plant. Sisal is mainly used to make rope. But because the word Bristle was used and not sisal this has led many to believe the fibre had come from pig bristle or horse hair, however, this is a total myth!

The natural fibre of the sisal meant this board would self-heal and the board again initially screen-printed black allowed for many variations of colour to be used.

The process of making a sisal dartboard

For many years the sisal dartboard has been the dartboard of choose. The construction hardly changed. The printed playing surface would then have a wire frame, known as the spiders-web or just spider, pinned to it to firmly divide the scoring segments. In recent years the top of the range dartboards now have a razor-edge wire inserted into the sisal. This is sometimes called blade wiring. The blade divider allows for more of the scoring area to be hit. This is because it is not only thinner than the previous spider wires, it also doesn’t require any additional pinning.

Watch a London Dartboard Being Made

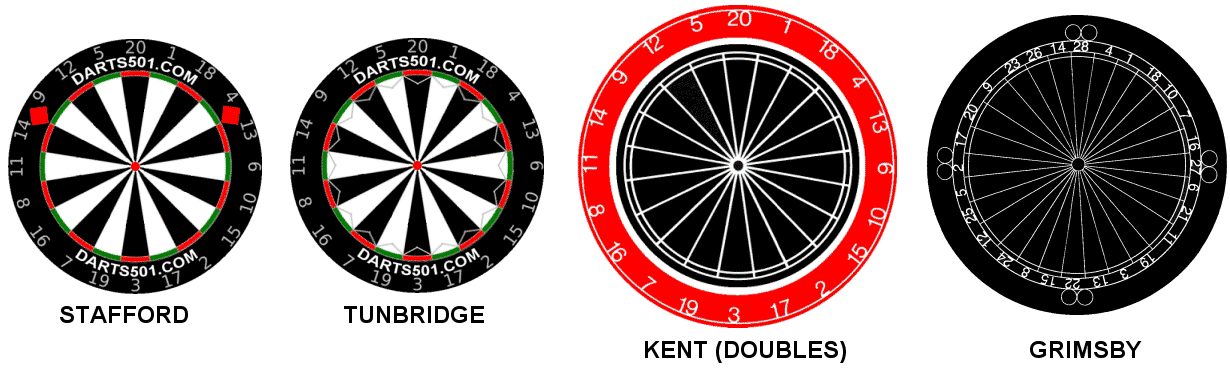

1. The sisal is washed and prepared and then compressed

2. The sisal is wrapped with thin film and cut in ‘biscuits’

3. 20 sisal biscuits are then formed to make the board

4. The excess sisal is then sanded to make a smooth surface

5.The playing surface is then screen printed red/green

6. The final black screen is then added to finish the printing

7. The blade edge wire is then compressed into the board

8. The finished board is expected and then ready for packaging

The Nodor Dartboard company is now part of a bigger group Winmau, Red Dragon but they still use what I consider to be the best sisal in the World from Kenya. This sisal is used to make the Nodor and Winmau dartboards today. In my opinion, they out perform and last better than alternative dartboards that are made from sisal obtained from Asia. The sisal is softer, less brittle and remains in place longer than most other dartboards.

![]()

Paper Dartboards

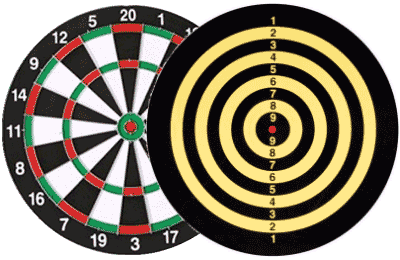

Dartboards have also been made using coiled paper. The centre bullseyes are usually made from a dowel rod and then a glued continuous piece of paper is tightly wrapped around it until the circumference is that of a dartboard. These boards were never to be played on as a serious playing surface but more for a child's first dartboard! The boards were usually two-sided. On one side the board would have the construction of a London Clock board while the other would feature a concentric circuit target area.

These boards were light in construction and cheap to produce. However, any serious dart player would not purchase these opting for a more durable and officially approved sisal dartboard.

The official London / Clock dartboard scoring segment area sizes can be found here:

You will also find a lot more fascinating facts about darts, regional dartboards, games on this website. I leave you to explore. Enjoy!

Acknowledgements | Privacy, Cookies & Terms of Use | FAQ